Through innovation and technology advancement, Shimco consistently continues to produce the highest quality parts for our valued customers. All manufacturing processes are analyzed by our expert production team to optimize the process for resourceful, consistent and cost-effective production. For manufacturing, we achieve maximum efficiency by designing and manufacturing the work-holding fixture for the machining operations. For forming, we use various jigs, press and roller equipment to meet specification. Our Quality Assurance department ensures dimensional inspection is done on-site throughout the production process. We also coordinate with our vendors to meet any heat-treating and surface finishing requirements. Starting in 2021, we will offer surface finishing in-house. Once produced, parts can be marked onsite using one of our ink-jet part marking machines before being carefully packaged and shipped to our customer.

Aluminum

Overall Part Dimensions: 16.2" X 4.9" X 0.023"

Primary Process: Shear / Saw / CNC Machine / Deburr / Form

Secondary Process: Surface Finish / Final QA / FAIR

- Length: 16.2"

- Width: 4.9"

- Thickness: 0.023"

- Tightest Tolerances: +/- 0.002"

- Material: 1100H19 Aluminum

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 97

Machined/Formed

Overall Part Dimensions: 5.7" X 3.4" X 0.187"

Primary Process: Shear / Saw / CNC Machine / Deburr

Secondary Process: Surface Finish / Part Mark / Final QA / FAIR

- Length: 5.7"

- Width: 3.4"

- Thickness: 0.187"

- Tightest Tolerances: +/- 0.002"

- Material: 302/304 Annealed Stainless Steel

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 73

Machined/Formed

Overall Part Dimensions: 5.7" X 3.6" X 0.02"

Primary Process: Shear / Saw / CNC Machine / Deburr / Form

Secondary Process: Surface Finish / Final QA / FAIR

- Length: 5.7"

- Width: 3.6"

- Thickness: 0.02"

- Tightest Tolerances: +/- 0.002"

- Material: 321 Annealed Stainless Steel

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 59

Machined/Formed

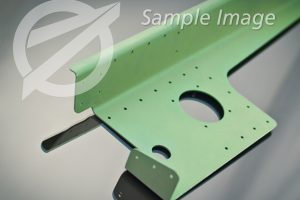

Overall Part Dimensions: 9.2" X 6.3" X 0.125"

Primary Process: Shear / Saw / CNC Machine / Deburr / Form

Secondary Process: Surface Finish / Part Mark / Final QA / FAIR

- Length: 9.2"

- Width: 6.3"

- Thickness: 0.125"

- Tightest Tolerances: +/- 0.002"

- Material: Carbon Steel 1008/1010

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 163

Machined/Formed

Overall Part Dimensions: 3.9" X 4.2" X 0.63"

Primary Process: Shear / Saw / CNC Machine / Deburr

Secondary Process: Surface Finish / Bag / Part Mark / Final QA / FAIR

- Length: 3.9"

- Width: 4.2"

- Thickness: 0.63"

- Tightest Tolerances: +/- 0.002"

- Material: Titanium CP1 GR4

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 216