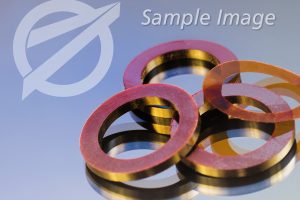

Shimco can produce washers and spacers from a wide variety of materials to meet the requirements of our valued customers. Where required, parts are marked with identification numbers before undergoing a rigorous final quality control inspection to ensure we meet the tightest of tolerances as required by our customers’ specifications.

Stainless Steel

Overall Part Dimensions: 6.7" X 6.7" X 0.180"

Primary Process: Shear / Machine / Drill

Secondary Process: Engrave / Final QA

- Length: 6.7"

- Width: 6.7"

- Thickness: 0.180"

- Tightest Tolerances: +/- 0.002"

- Material: 15-5PH Stainless Steel

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 160

Overall Part Dimensions: 5.53" X 5.53" X 0.17"

Primary Process: Shear / Stamp

Secondary Process: Heat Treat / Surface Finish / Final QA / FAIR

- Length: 5.53"

- Width: 5.53"

- Thickness: 0.17"

- Tightest Tolerances: +/- 0.002"

- Material: Blue Tempered Spring Steel BTSS 1074/75

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 48

Overall Part Dimensions: 1.575" X 1.575" X 0.032"

Primary Process: Shear / Laser Cut

Secondary Process: Heat Treat / Surface Finish / Final QA / FAIR

- Length: 1.575"

- Width: 1.575"

- Thickness: 0.032"

- Tightest Tolerances: +/- 0.002"

- Material: Carbon Steel 1008/1010

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 65

Nylons & Teflon

Overall Part Dimensions: 0.620" X 0.620" X 0.40"

Primary Process: Shear / Turn / Drill

Secondary Process:Final QA

- Length: 0.620"

- Width: 0.620"

- Thickness: 0.40"

- Tightest Tolerances: +/- 0.002"

- Material: Nylon

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 400