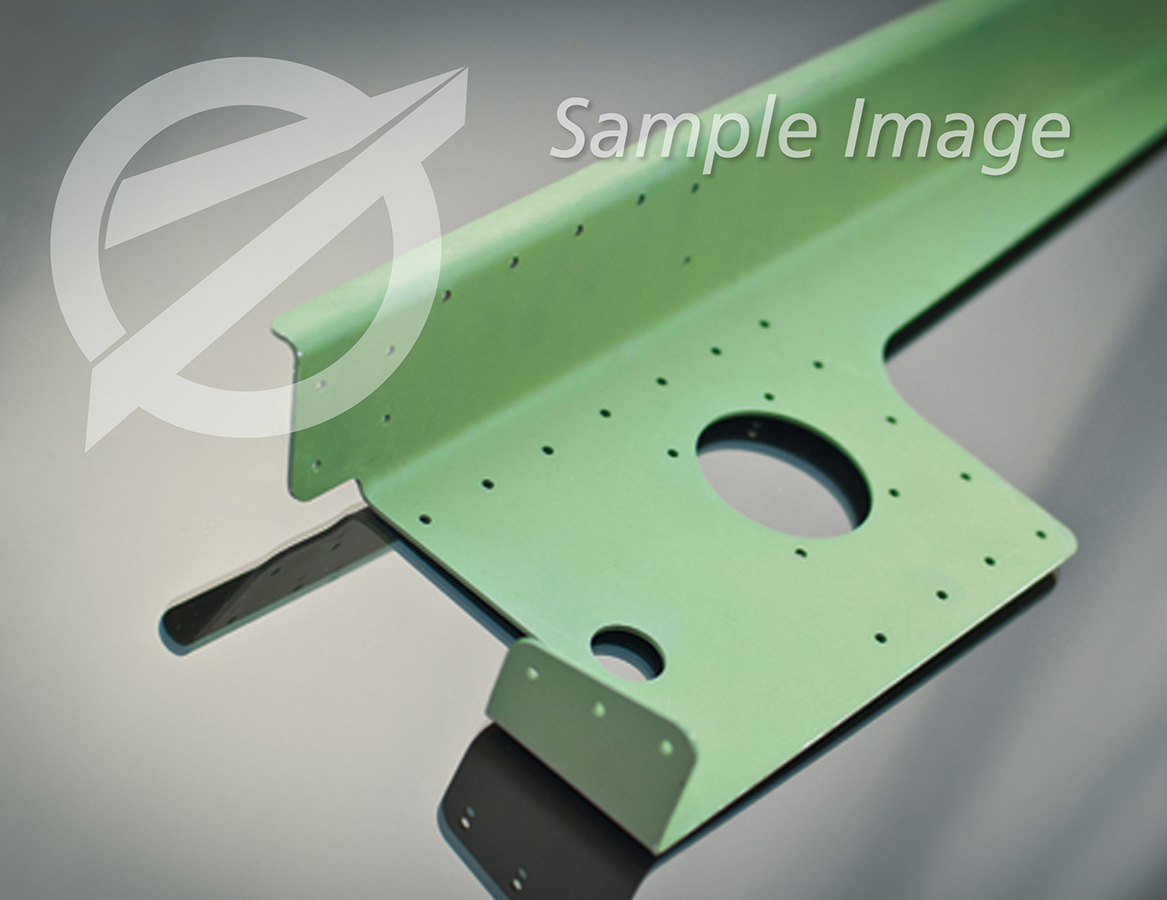

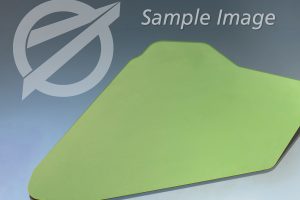

Sample CNC Machined and Formed Stainless Steel Shims

SAMPLE 321 Annealed Stainless Steel Shims

Overall Part Dimensions: 5.7" X 3.6" X 0.02"

Primary Process: Shear / Saw / CNC Machine / Deburr / Form

Secondary Process: Surface Finish / Final QA / FAIR

- Length: 5.7"

- Width: 3.6"

- Thickness: 0.02"

- Tightest Tolerances: +/- 0.002"

- Material: 321 Annealed Stainless Steel

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 59

| Primary Process | Shear, Saw, CNC Machining, Deburr, Form |

|---|---|

| Secondary Process | Surface finish, Final Quality Assurance, FAIR |

| Overall Part Dimensions | 5.7" X 3.6" X 0.02" |

| Length | 5.7" |

| Width | 3.6" |

| Thickness | 0.02" |

| Tightest Tolerances | +/-0.002" |

| Material | 321 Annealed Stainless Steel |

| Testing | In Process Inspection, Final QA, FAIR |

| Production Volume | 59 |

Only logged in customers who have purchased this product may leave a review.

Related products

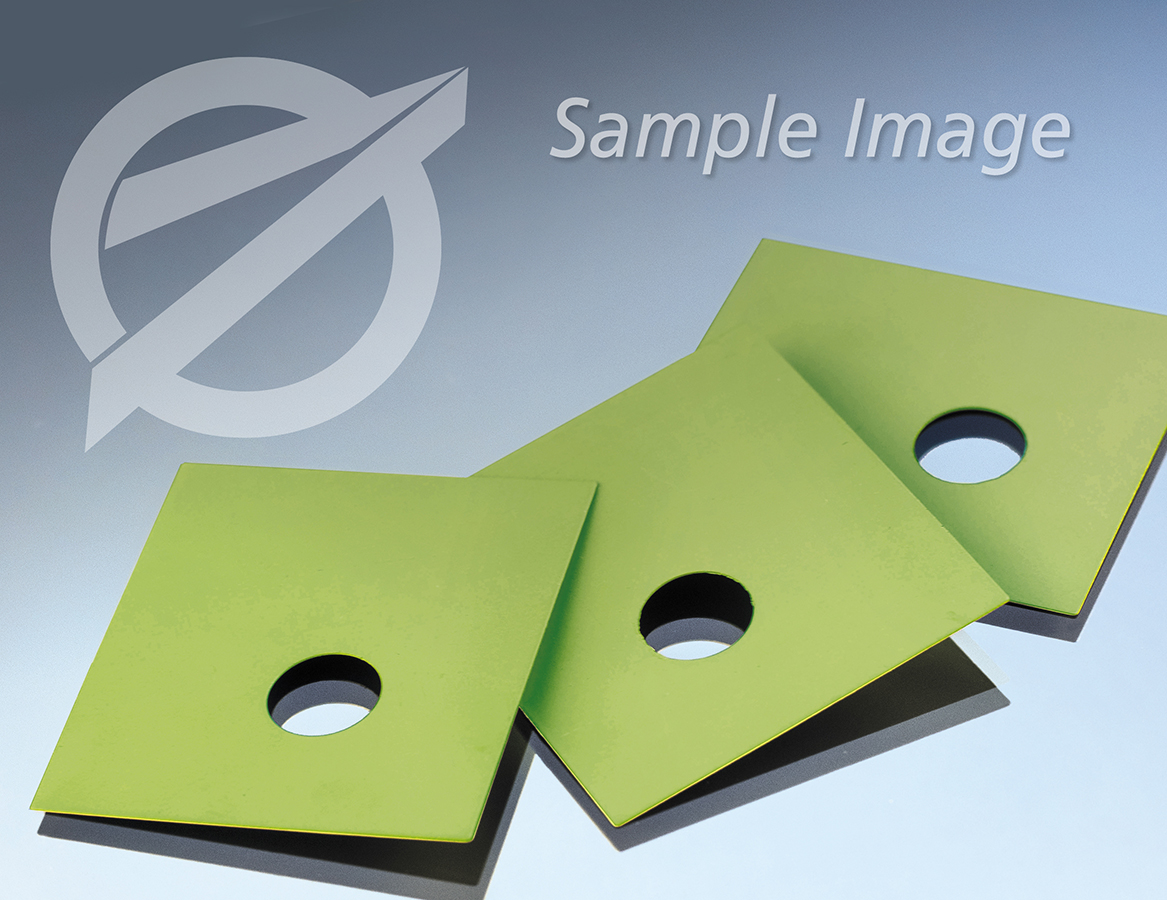

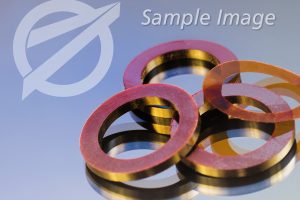

Washers/Spacers

Overall Part Dimensions: 6.7" X 6.7" X 0.180"

Primary Process: Shear / Machine / Drill

Secondary Process: Engrave / Final QA

- Length: 6.7"

- Width: 6.7"

- Thickness: 0.180"

- Tightest Tolerances: +/- 0.002"

- Material: 15-5PH Stainless Steel

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 160

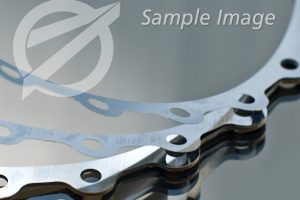

Machined/Formed

Overall Part Dimensions: 3.9" X 4.2" X 0.63"

Primary Process: Shear / Saw / CNC Machine / Deburr

Secondary Process: Surface Finish / Bag / Part Mark / Final QA / FAIR

- Length: 3.9"

- Width: 4.2"

- Thickness: 0.63"

- Tightest Tolerances: +/- 0.002"

- Material: Titanium CP1 GR4

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 216

Edgebonded Shims

Overall Part Dimensions: 12" X 12" X 0.220"

Primary Process: Auto Shearing / CNC Machining / Drilling / Milling

Secondary Process: Edgebonding / Part Marking / Final Quality Assurance

- Length: 12"

- Width: 12"

- Thickness: 0.220"

- Tightest Tolerances: +/- 0.002"

- Material: Stainless Steel 302 Annealed

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 220

Laminated Shims

Overall Part Dimensions: 4.70" X 3.15" X 0.110"

Primary Process: Press / Shearing / CNC Machining / Drilling / Milling

Secondary Process: Deburring / Outside Processing / Part Marking / Final Quality Assurance

- Length: 4.70"

- Width: 3.15"

- Thickness: 0.110"

- Tightest Tolerances: +/- 0.002"

- Material: Laminated Stainless Steel 302 Full Hard

- Testing: In Process Inspection: / Final QA / FAIR

- Production Volume: 144

Machined/Formed

Overall Part Dimensions: 9.2" X 6.3" X 0.125"

Primary Process: Shear / Saw / CNC Machine / Deburr / Form

Secondary Process: Surface Finish / Part Mark / Final QA / FAIR

- Length: 9.2"

- Width: 6.3"

- Thickness: 0.125"

- Tightest Tolerances: +/- 0.002"

- Material: Carbon Steel 1008/1010

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 163

Solid Shims

Overall Part Dimensions: 4.32" X 4.32" X 0.016"

Primary Process: Shear / Saw / CNC Machine / Deburr

Secondary Process: Engrave / Final QA / FAIR

- Length: 4.32"

- Width: 4.32"

- Thickness: 0.016"

- Tightest Tolerances: +/- 0.002"

- Material: 13-8MO Stainless Steel

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 155

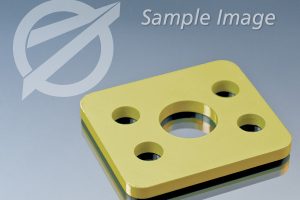

Machined/Formed

Overall Part Dimensions: 5.7" X 3.4" X 0.187"

Primary Process: Shear / Saw / CNC Machine / Deburr

Secondary Process: Surface Finish / Part Mark / Final QA / FAIR

- Length: 5.7"

- Width: 3.4"

- Thickness: 0.187"

- Tightest Tolerances: +/- 0.002"

- Material: 302/304 Annealed Stainless Steel

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: 73

Edgebonded Shims

Overall Part Dimensions: 16" X 16" X 0.500"

Primary Process: Auto Shearing / CNC Machining / Drilling / Milling

Secondary Process: Edgebonding / Part Marking / Final Quality Assurance

- Length: 16"

- Width: 16"

- Thickness: 0.500"

- Tightest Tolerances: +/- 0.002"

- Material: Stainless Steel 301 1/4 Hard

- Testing: In Process Inspection / Final QA / FAIR

- Production Volume: N/A

Reviews

There are no reviews yet.