The two companies have entered into a development agreement to produce a new product range for aerospace applications.

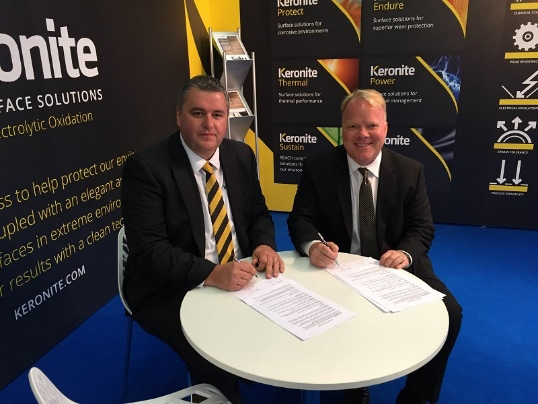

MARKHAM, Ontario(June 19, 2015)–Shimco,a world-wide leader in the manufacture of precision parts and gap management solutions, announced today the signing of a Memorandum of Understanding (MOU) with a dvanced surface solutions company Keronite for the development of metallic, solid and peelable shims in aluminium and titanium for aerospace applications.

The MOU will see the two companies combining technologies to develop a new, environmentally-clean range of products for entry into service over the next 12 – 18 months.

Commenting on the partnership, Matt Hamblin, CEO of Keronite, said: “I’m really pleased that we’ve completed this deal at our inaugural Paris Airshow. This partnership will enable both Keronite and Shimco to bring together the benefits of our combined technologies to offer something new to our aerospace customers.

“As a clean technology, Keronite provides an environmentally-friendly, cost-effective alternative to traditional surface treatments and the fact it can be tailored to provide differing performance characteristics at different points on a component means it’s a truly enabling, flexible solution.”

Matt Hamblin (left), CEO of Keronite and Peter Voss (right), President, CEO and owner of Shimco

Peter Voss, President,CEO and owner of Shimco, added: “We’re excited by the potential offered by this agreement with Keronite, which will allow us to develop a variety of aluminium and titanium products for aerospace with enhanced performance characteristics.

Shims are thin, often tapered or wedge-shaped pieces of material that are used to fill small gaps or spaces between assembly items. In particular, they are often used as spacers, filling gaps between component parts that are subject to wear and tear.

The Keronite system is the world’s most advanced electro-chemical surface treatment for light alloys. It enhances material properties by converting the alloy surface to a hard ceramic coating that grows into and out from the alloy surface. Typical benefits include improved alloy strength, wear resistance, chemical stability, thermal and electrical performance.

About Keronite

Keronite is the world’s most advanced surface treatment for light alloys such as aluminium, magnesium and titanium. A patented, industrially-proven, clean technology, the Keronite process produces hard, dense ceramic surface layers that enhance the durability of components by delivering wear resistance and corrosion protection in the most demanding of applications, such as aerospace, medical, oil and gas and automotive.

Keronite is owned by Azini Capital, which acquired its interest in the business in 2007. For further information, visit www.keronite.com

About Shimco

For over 25 years, Shimco has served the aerospace, defense, space, industrial and other sectors worldwide. Shimco is a world-wide leader in the manufacture of precision parts and gap management solutions (such as laminated and edge-bonded shims, tapers and spacers),in materials ranging from aluminum and titanium through to synthetics and composites.

Shimco offers a tradition of innovation,precision and execution, providing solutions that conform to exacting international and customer-specific standards. Shimco is registered with the Canadian Controlled Goods Program and is an ISO9001:2008 & AS9100C registered company. Their commitment to quality, on-time delivery, lean manufacturing, customer support, the environment and financial strength is unparalleled. Canadian Headquarters are located in Markham, Ontario.

We are dedicated to be a preferred strategic partner to global aerospace, space and defence OEMs and Tier 1 system integrators, suppliers and MRO organizations, providing value and service on everything that flies.

Visit: www.shimco-nd.dev.seoprrank.com

Shimco. Experience The Perfect Fit™